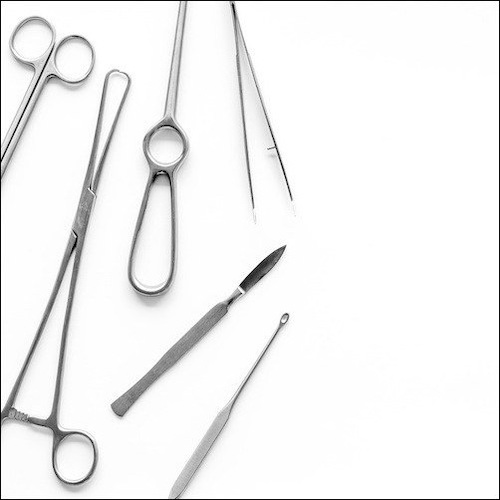

H.H. Arnold Co. specializes in grinding services, and we perform a wide variety for medical applications. We use services like CNC turning and CNC vertical milling to tailor products to precise customer specifications.

Why H.H. Arnold Co.?

Why H.H. Arnold Co.?

The medical industry relies on our CNC machining processes to realize our customers’ ideas. Below, we’ve outlined some of our main processes and capabilities:

- Turning: CNC and conventional turning have bar feed capabilities of diameters up to 2.5” plus chucking of up to 12” width by 21” length, and conventional turning has up to 16” × 40” swing between centers.

- Milling: CNC milling and manual milling operate both vertically and horizontally at capacities of up to 20” × 40” × 25”, and conventional millers operate with cubes of 10” × 44” × 16” or more.

- Grinding: H.H. Arnold can grind materials to diameters ranging from 0.03” to 14”. Our grinders also have shaft length capacities of up to 40” and internal grinding capabilities of 16” swing and 8” depth.

- Honing: Our honing capabilities range from 0.125” to 6” in diameter, with maximum lengths of 20” and surface finishes of up to 8 microinches.

Why H.H. Arnold Co.?

Why H.H. Arnold Co.?